SIM Technologies Pvt. Ltd. is a Chennai based CAD/CAM/CAE solutions provider and authorized reseller for Mastercam and SolidWorks softwares in South India. SIM Tech has proven expertise in post processor customization and development for various controllers like Siemens, Fanuc, Heidenhain, Fagor, OSPL, etc.

SIM Tech has successfully proven and implemented Eccentric CAM grinding techniques using Mastercam software for CNC turn- mill and grinding machines across various Industries like Parishudh Machines Pvt Ltd - Ghaziabad, Karnavati Engineering Limited – Ahmedabad and others.

Project:

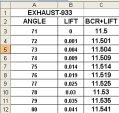

The CAM grinding application includes creating the cam profile from theoretical values of base circle diameter, lift corresponding to the angle, the generation of NC codes according to the controller (Siemens, Fanuc, etc) for the CNC machines.

Parishudh Machines Pvt ltd, a CNC machine tools company manufactures cam grinding machines for various applications. They found difficulty in creating cam profiles for their customers' requirements as they do a very tedious calculations using AutoCAD and then take that profile to machining.

The profile for different cams like Knife, Roller and Flat can be easily created in Mastercam from the BCD and lift details of the cam. The theoretical details are directly imported in to Mastercam using ASCII file converter and later joined through splines, and smoother toolpath generated for different cam profiles. Typically manual C-axis programs for cam profiles generated on angle increments, but the geometry accuracy lost in the lift area, where profile requires additional co-ordinates. Mastercam software provides advantage of adding optimized smooth profile based upon the input curvature and tolerance provided. Through this process cam profile accuracy will be maintained and verification of the profile can be simulated before manufacturing.

The profile generation for knife edged and roller followers can be directly created with the angle/lift data and for the flat edged follower a special macro is used to develop the cam profile.

In the above picture the first profile is the actual cam profile created for a flat edged follower and the later is the practical cam profile created through Mastercam software which will used for programming.

NC codes generation:

The developed cam profile can be easily programmed using Mastercam's C- Axis toolpaths. Using the simulation option in Mastercam one can easily check the compatibility of the grinding wheel with the cam profile. Once the toolpath has been developed the NC codes are posted in an editor.